Call Us

Mail To

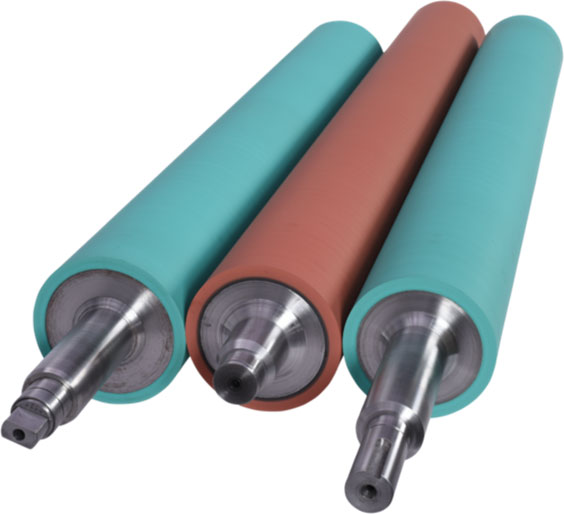

Dalwyn Group offers precision‑engineered rubber components across a spectrum of high‑performance elastomers. Our manufacturing partners supply advanced compounds and molding processes to deliver consistent quality, tight tolerances, and tailored material properties.

Key Rubber Grades

- EPDM (Ethylene Propylene Diene): Excellent ozone, weather, and heat resistance; low compression set; Shore A 40–90.

- NBR (Nitrile Butadiene): Superior oil, fuel, and solvent resistance; good mechanical strength; Shore A 50–90.

- SBR (Styrene Butadiene): High abrasion resistance and heat aging; general‑purpose elastomer; Shore A 60–90.

- CR (Neoprene): Broad chemical resistance, flame retardant; Shore A 50–80.

- IIR (Butyl): Exceptional gas impermeability; low permeability; Shore A 40–75.

- FKM (Viton®): Outstanding high‑temperature and chemical resistance; Shore A 60–90.

- HNBR (Hydrogenated NBR): Enhanced heat, ozone, and wear resistance; Shore A 70–90.

- ACM (Polyacrylate): High heat and oil resistance; Shore A 60–80.

- CSM (Chlorosulfonated PE): Chemical and UV stability; Shore A 50–80.

- FFKM (Perfluoroelastomer): Peak chemical and thermal performance to 300 °C; Shore A 70–90.

- Silicone: Extreme temperature flexibility (−60 °C to 230 °C); biocompatible; Shore A 30–70.

- TPU & TPE: Thermoplastic elastomers for dynamic sealing and extrusion applications.

Manufacturing Processes

- Injection Molding & Transfer Molding for complex geometries and integrated-metal parts

- Compression Molding for large seals, diaphragms, and gaskets

- Extrusion & Calendaring for O‑rings, custom profiles, tubing, and sheets

- Rubber-to‑Metal Bonding for vibration isolators, engine mounts, and bonded seals

- Precision Finishing including CNC lathe turning, grinding, and post‑cure vulcanization

Dalwyn’s rubber solutions are engineered to meet ASTM and ISO specifications for tensile strength (ASTM D412), compression set (ASTM D395), abrasion resistance (ASTM D5963), and low‑temperature flexibility, ensuring reliability in automotive, industrial machinery, mining, and cold‑climate applications.